When relocating production lines or complex interconnected machinery, auditing an existing installation plays a vital role as it lays the foundations for a vertical start up.

Typically the audit consists of the following:

We view the machinery in production to gain a greater understanding of the machinery and the end product.

Also this allows us to take certain readings:

In addition, we use photographs and video footage to highlight discrepancies and aid the installation. Once an audit is completed we can then inform our customers of any potentially adverse issues prior to relocation.

Once the machine(s) become the responsibility of RJB our removal team of highly experienced electrical &

mechanical engineers, study the audit notes to ensure nothing has been overlooked. They isolate and disconnect

any site services, make the remaining supply safe and record useful information on the removal document.

With the machines isolated from site services the team then set about any interconnections from adjacent machines,

electrical cabinets or hydraulic power packs, taking care not to misplace any fixings and label all cables and their

locations, creating a comprehensive document for reference when installing the machinery.

The separated machines are moved to a storage area ready to be packed / loaded for transportation to the new destination.

On arrival in their new location, the machines are unloaded by our engineers, unpacked and placed

into a storage area ready for installation.

The installation team refer to the audit notes and factory layout to determine the centre line and

datums of the machines, as well as the general footprint, using laser equipment for optimum accuracy.

The machines are set in place methodically, the customer checks the position is practical and the

machines are then levelled using highly accurate equipment.

With the machines in place the team reconnect the interconnections using the labels and removal

documentation as a reference, as well as the site services required to save dealing with additional contractors.

To achieve the optimum 'Vertical Start Up' our engineers perform the following operations:

Yellow lining consists of our electrical engineer(s) checking all electrical connections made by other engineer(s) to the removal document and the machine drawings for clarification. This prevents any cables being misplaced or connected incorrectly according to the drawings or original installation.

Insulation Resistance Tests are performed to ensure that no cables have been damaged during the relocation process and allow RJB to power up all the machinery safely.

Static checks ensure all mechanical timings are correct. The machines are turned over by hand and watched so that critical components are not damaged by other parts of the integrated machine. Dynamic checks ensure the machines are rotating correctly whilst being driven electrically.

Input checks consist of all the electrical components that send an input to the Plc being manually forced to check that the Plc is receiving the signals. Output checks consist of all the electrical components that are operated by the Plc are forced by the Plc to check that the components are operational and that the Plc is sending out the signal.

Shakedown is the first time the machines run once all the checks have been completed, its purpose is to make sure all connections are tight and haven't become loose in transit.

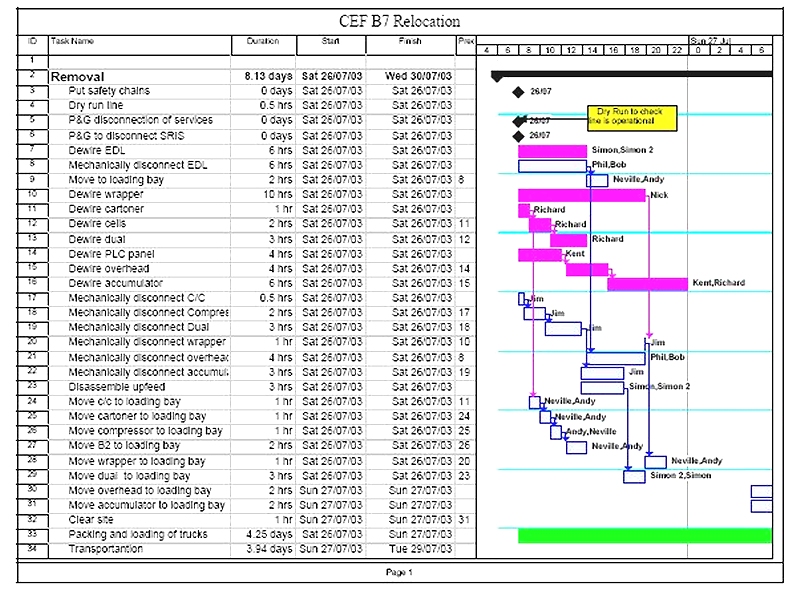

Dry Run is the final test of the machine before handover. It allows the customer see the machines running consistently without product to prove that there are no serious issues with the installation. Current, speed and temperature readings are taken at regular intervals to ensure that there are no irregular readings. Once the Dry Run is complete the machines are ready to run the product and we hand over to the customer.

On any relocation project RJB offer live operation support, where one of our engineers will remain on site after the relocation and dry run is complete. Our engineer will assist the customer's own team to fine tune the machinery, undertaking tests to ensure the smooth operation and successful output of product. Live operation support can also mean engineering changes once the machines are up and running to their original state.